What is Quantra Vector?

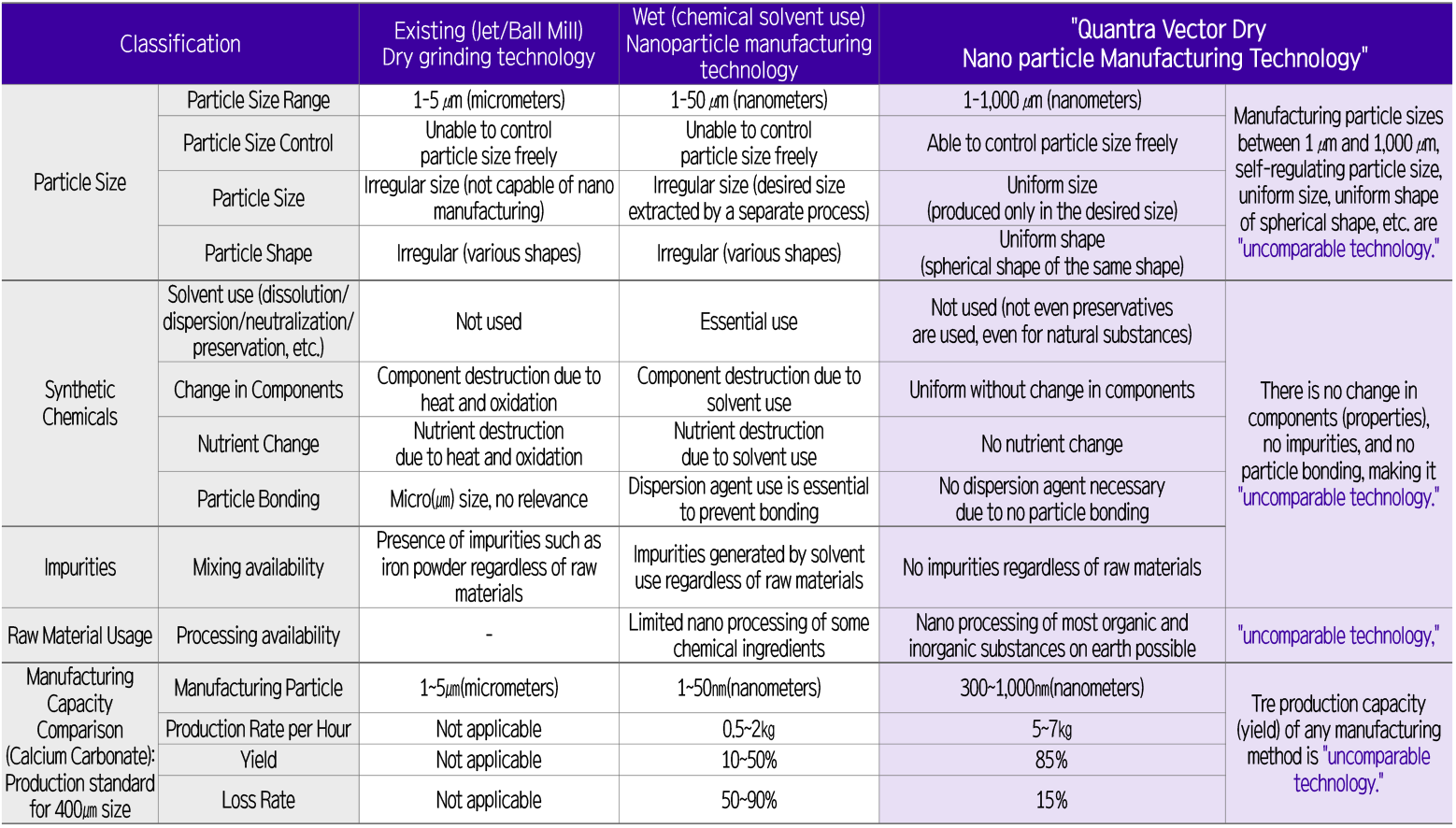

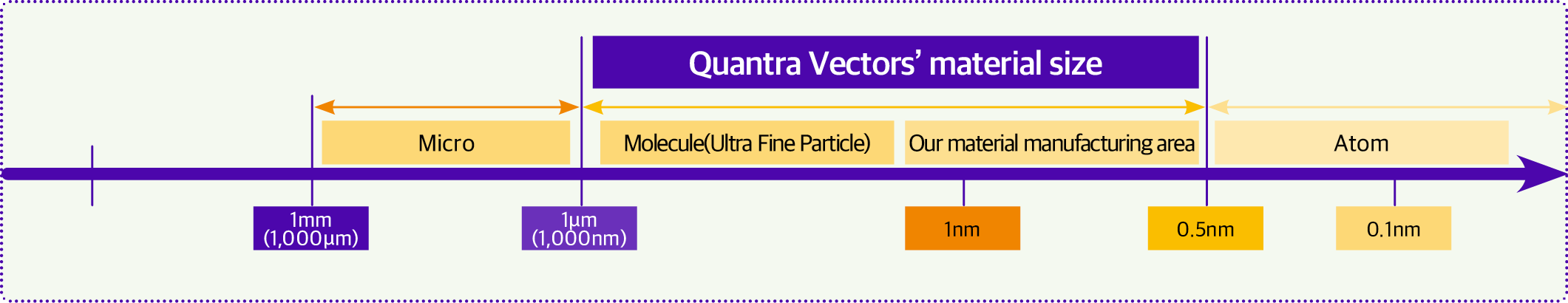

Quantra Vector Technology, based on quantum principles, addresses various issues in the material industry and introduces new possibilities. Our application of this technology has evolved into “Dry Nano-Grinding Technology,” enabling the production of pure new substances, maintaining their natural state, and revolutionizing innovative opportunities in material design and production by uniquely understanding and manipulating material properties. This technology significantly contributes to global industrial innovation and stands as a key technology leading the future material industry.